There’s an old saying in construction: measure twice, cut once. It’s a reminder that the best work starts with preparation—because once something is built, it’s built. You don’t get a second chance to get it right.

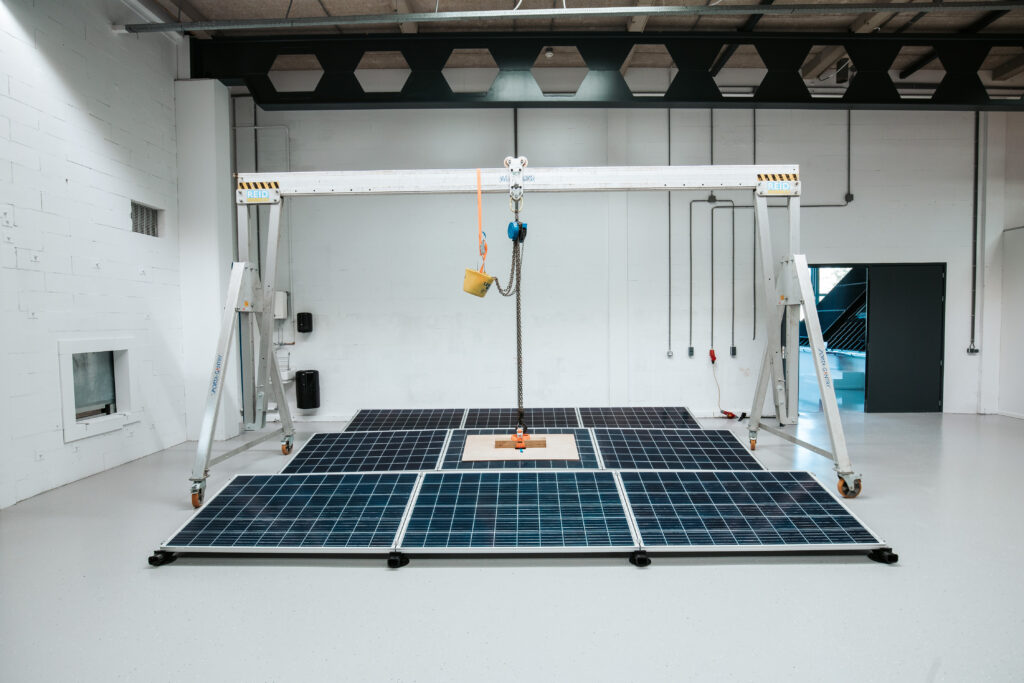

Preparation is critical to quality work. And in solar hardware, a key part of that preparation is testing. Before an Enstall system ever reaches a rooftop, it has to prove it can stand up to the real world—and then some. That’s why we put every component we make through the most rigorous testing in the industry.

From individual parts to full systems, our hardware is tested in labs across North America and Europe. We simulate scorching heat, freezing cold, hurricane-force winds, and corrosive salt air. Because once your system is installed, it needs to stay put—and stay strong and safe—for 25 years or more.

Installers know the mounting system isn’t just hardware. It’s the foundation of the entire array. If it fails, the panels, the roof, and the project are all at risk. That’s why we stress-test every component—hooks, rails, clamps—under conditions that mirror the toughest environments on earth.

Our philosophy is simple: test more so you can worry less. When your hardware is built to withstand extremes, your installations are built to last.

Built for the Long Haul

A solar system’s lifespan is measured in decades—and its mounting hardware is the foundation. Poor-quality hardware can buckle, shift, or corrode over time—putting both the array and the building at risk.

That’s why Enstall’s internal testing simulates years of wear in days. We test for extreme temperatures, UV degradation, wind uplift, corrosion, and more. We measure load-bearing strength and performance across a wide range of materials and roof types.

Whether it’s a warehouse in the Texas sun or a home in the French Alps or along the Scandinavian coastline, installers can trust that our systems will hold—no matter what.

Third-Party Verified, Installer Trusted

Enstall’s testing doesn’t stop at our own labs. Our products are independently certified by third-party organizations to meet the highest safety and performance standards—giving installers added confidence no matter where they work.

In North America, that includes certification to UL (Underwriters Laboratories) safety standards. UL certification is a gold standard in product safety and code compliance. It requires rigorous, repeatable testing to meet standards like:

- UL 2703 – PV mounting systems

- UL 2703A – Flashing systems for weatherproofing

- UL 3741 – Firefighter safety and NEC 690.12 compliance

- UL 2239 / UL 1565 / UL 1741 – Supporting hardware and eBOS

Enstall is an Intertek Recognized Satellite Lab with Level 4 designation—the highest available—enabling in-house construction reviews, testing, and data collection. Multiple Enstall systems are UL 3741 Listed, offering installers and system designers a path to code compliance without needing module-level power electronics.

In the state of Florida, we meet the High Velocity Hurricane Zone (HVHZ) requirements via Florida Product Approvals (FLPA), including TAS-100A testing for wind and rain resistance—essential for permitting and long-term reliability in extreme weather zones.

While UL is primarily a North American standard, it is widely recognized and respected globally—including in European markets—where it adds an additional layer of validation. It complements CE marking and local testing regimes, helping Enstall provide a consistent quality benchmark across continents.

Ready for a Changing Climate

Solar is expanding rapidly—but so is the intensity of the environment it operates in. With hotter summers, fiercer storms, and more extreme weather, systems need to stand up to tomorrow’s challenges—not just today’s.

Enstall tests for durability under the harshest conditions. Our systems have outperformed competitors in real-world storms, including in hurricane-hit regions like Puerto Rico. When the weather turns, you want hardware that’s already been through the worst.

Global Footprint, Local Insight

With testing labs in California, the Netherlands, Germany, and Spain—and partnerships with top universities—our R&D is as global as our footprint. We know installers face different challenges in different regions. That’s why we test for snow loads in the Alps, salt spray on coastlines, and everything in between.

We’re always refining based on real-world feedback. Innovations like our new hook for Rosemary Tiles in the UK or our UL 2703A-certified HUG roof attachment in the U.S. show how local adaptation and high-performance testing go hand in hand.

The Confidence to Get on the Roof

Every installer knows the feeling of stepping onto a roof. The gear needs to work. The system needs to hold. That’s the confidence Enstall’s testing delivers. We’re measuring twice—so you don’t have to look back.

From safer installs to fewer call-backs, our commitment to testing is a commitment to the people who rely on our systems every day.

Because in solar, nothing matters more than trust—and trust starts with testing.